When you are building luxury semi-custom performance yachts 7,000 miles away from your main market you’d better get everything right first time. So far so good!

For Southern Wind, the delivery of each new yacht from their yard in Cape Town, South Africa usually means a passage of 7,000 miles for those heading to the Mediterranean. Little surprise then that a solid build and a reliable yacht has been one of their core values from the beginning. Since their foundation in 1991 Southern Wind have been acutely aware of their geographical distance from the yachting mainstream. They have not only built their business around it but have turned the distance to their advantage.

‘We have to be capable of building pretty much everything in-house,’ says commercial director Andrea Micheli. ‘Reliability is key but timing is also a big priority for us throughout the production process.’ All of which has seen the company become experts in semi-custom production.

It’s an expression that means different things to different ends of the boat building scene. For series production builders, semi-custom can often simply refer to a long options list while for high-end shipyards it means a common hull, different decks and a free hand on the interior layout.

For Southern Wind, semi-custom is a way of thinking as well as a smart and versatile way of building that provides a raft of benefits from cost savings to solid reliability, great support and backup and in many cases, a wider range of choice than most would expect.

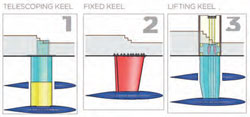

Below: the SW105 is designed to take three keel options This flexibility is a key aspect of the shipyardʼs philosophy to meet different ownersʼ range of expectations

‘Our perfect customer is one who is scratching their head wondering whether to go down the custom path or not,’ continues Micheli. ‘This is a great starting point for us because, having been down this route several times before we know that there are so many advantages in a semicustom build, which could effectively turn into a “smart” custom.

‘It’s not that we don’t believe in custom build, we do, there are plenty of reasons as to why a client might want to pursue this. But we know that over the course of the entire project there will be a number of areas where we can build far more efficiently and accurately. Take tooling as an example.

‘Sharing the tooling costs is not only more efficient financially, we can invest more money in higher quality tools as well. In addition, we can collect accurate data more quickly, which in turn helps when it comes to working through feasibility and weight studies. This has a knock-on effect because it broadens the range of options that can be investigated rather than narrowing them down.’

Having built 13 SW100s and five SW102s (plus ten 90-96 footers) it is easy to see why Micheli speaks with such confidence, especially with a fourth new SW105 in build. Few other yards in the world, if any, have such concentrated experience in this size and style of superyacht.

Southern Wind’s knowledge and experience goes far deeper than simply anticipating an internal layout or deck specification. Farr Yacht Design has worked with them for many years and vice president and senior naval architect Jim Schmicker knows this approach well. ‘One of the pleasures of working with Southern Wind is their accurate assessment of the build weights,’ he says. ‘And that's not something you always get from other yards.’

‘Depending on the on the final hull shape, the interior layout and what the machinery and deck hardware is going to be, they know what their yachts will weigh and that is how they come out. Throughout the yard, every couple of metres, there's a big sign that says, “Weigh what you put in the boat.” And they do.’

Having an accurate handle on displacement and on centre of gravity are two of the fundamental factors when it comes to working up any design. It also allows the yard to make more accurate estimates on cost and therefore help the entire process, from selling to delivery.

‘When you are considering a particular style of boat at a particular spot on the performance spectrum while adopting a particular level of technology, there is a weight associated with it,’ Schmicker continues. ‘From there we know that the keel needs to be a particular configuration, so we then know the size of the rig and what it is going to weigh. From there we cross-check with the huge database of boats we've been doing with them for the past 30 years, before saying how the design will slot into their range.

‘Southern Wind can then figure out precisely what their cost is going to be and present it to the potential buyers. They are very accurate and owners really appreciate when they say it's going to cost this much and they stick to it.’ Micheli adds that ‘transparency in all phases of the design and construction process is one of our main core values’

Of the many 100 footers that Southern Wind has produced, the SW105 is the best current example of how the variety of options play out within a versatile platform. So how and where does the process start?

‘All the rigs are positioned in the same place. We don't try to move those around,’ Schmicker says. ‘ But the boats have different decks and Southern Wind is clever when it comes to installing them. They dry fit the deck first, take it off to do the interior installation and then do the final installation of the deck at quite a late stage in the construction.

‘So while the mast bulkhead needs to be in a given position, you can pretty much move things around as you wish such as cabins, galleys, that sort of thing.’

Hull construction can also vary more than clients expect, Micheli explains. ‘Simply changing the hull laminate material while retaining the same process and hull lines delivers big potential advantages,’ he says. ‘The SW105s hulls are an infused Corecell sandwich construction. The first boat Satisfaction had an hybrid Aramid outer skin and carbon inner skin whereas the second boat Kiboko Tres was full carbon laminate, which saved almost 500kg.

‘Some clients do ask about pre-preg laminates and boat number four will have a full carbon hull with Nomex and pre-preg foredeck and cockpit. Along with some other key areas of weight optimisation this boat will be more than three tonnes lighter than her sisterships, with a higher righting moment.’

The most obvious differences between the current crop of SW105s are also the best visual examples as to the variety of approaches that are possible with the semi-custom approach: the decks. ‘We have a deck saloon, a raised saloon and what we call a GT version that has a very sleek, low coachroof,’ Micheli says. ‘With a sporty deck the boat looks completely different. We have options for lower freeboards, a different deck, different keel configurations, different masts but the design platform is the same.’

While the decks are varied so too are the keels, which play a key part influencing other areas of the design.

Above: all hulls are laminated using vacuum infusion techniques with three-part tooling. Smart design and construction techniques allow owners to customise the design of their deck, cockpit and coachroof, giving each yacht its own individual personality.

Below: SW105 hull number one Satisfaction covered more than 35,000 nautical miles of cruising in two years, proving her dependability and achieving the ownerʼs desire for a fast and exhilarating sailing experience without compromising on comfort

‘From Day One we thought it would be good to offer three keel options: fixed, lifting and telescopic keels,’ Micheli says. ‘By considering this from the start we could then think about the implications for the engine room and how that affected the saloon. This enabled us to fix its position while allowing us to keep the three keel options.

‘We then looked at the height of the engine room and how that would affect the various deck options. Our tooling is set up so we can alter the camber of the deck mould, which will cater for boats of up to 140ft long. We then have semi-custom moulds for the coachroof and the cockpit so we can vary the height for decks.

‘When the owner of SW105 number four asked for a completely different deck we didn’t have to redesign and charge for the entire deck tooling and design. Instead, we just charged for the modification work on the coachroof and the cockpit which was half the cost of a new custom deck mould and tooling.’

‘We give you a well tried-andtested platform and we offer you options. If you ask for an option that we have never sold, then we develop it for you. If a client has stronger opinions, we push the boundary of the customisation more. If on the other hand the client wants a faster and already well proven option, we offer ideas based on configurations that we have already built.

‘Clients who have strong ideas in some areas don’t necessarily need to write the specs for the rest of the yacht but they can still influence in the areas that are important to them.

‘One example is technical systems, where we know that the equipment selection and installations perform well, having been tried and tested. All systems are standard across many Southern Wind yachts and the crews have all been trained in the same way. Even though the systems are being refined with each new build, the crews know them well enough to understand the SWS philosophy, which makes it easier to switch from boat to boat and from project to project.’

Scenarios like these start to highlight the benefits to both client and builder of drawing from previous experience and complementing them with new ideas and configurations. So while semi-custom may mean different things to different people, experience is what counts – Micheli is certain of it.

‘So long as we have the opportunity to put our experience on the table we can be confident of meeting the owner’s expectations.’

Click here for more information on Southern Wind Yachts »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store