To improve behaviour it is first essential to put in place a reliable means with which to monitor progress

Wouldn’t it be great, when we buy things like sails, blocks, ropes, wet weather gear, antifoul paint – or even a whole new boat – to be able to make informed ethical choices and support brands that respect the environment and human health? We can already do that when buying cars, appliances, coffee and many other products, so why not marine kit and boats? There will soon be an efficient way for marine designers and manufacturers who care about the environment – and many of them do – to improve the sustainability and overall environmental impact of their products and services, and to show their customers what they’ve achieved. It’s called MarineShift360.

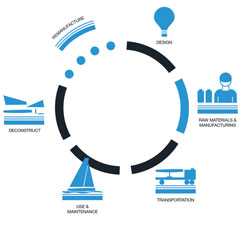

The key to this is a business process called life cycle assessment (LCA), which tracks and calculates the sustainability of products all the way from sourcing and transport of raw materials, through manufacture, packaging, distribution, retail and use, to recycling or disposal. Only by considering the entire life cycle of a product can we assess its impact on the environment in a meaningful way. Designers can make responsible choices while selecting materials and production processes, and ultimately create a product that is better for the consumers and the planet.

It’s an approach that has become common – in some cases legislated – across many industries, including construction, aerospace, automotive and apparel, as manufacturers have worked to better understand their products and mitigate their impacts. Companies such as Canon, Levi Strauss, Kraft Foods and Mazda have used in-house LCA tools to lower carbon emissions, reduce packaging and lower energy usage. The LCA studies that support these changes allow companies to communicate their efforts to consumers with heightened credibility.

Why should we care? Our manufacturing activities impact the use of non-renewable energy sources, production of plastic waste, polluting emissions into air and water, not to mention the ever-increasing issue of what to do with all the yachts that are coming to their end of life. The marine industry still mostly operates with a linear take-make-waste approach; LCA offers the first step towards a circular model that aims for the elimination of waste through clever design of products. Life cycle assessment makes sound economic sense for a boatbuilder: if sustainable design choices help to sell just one more yacht, LCA analysis has probably paid for itself many times over. For a community that relies so heavily on a healthy environment for our work, our enjoyment and our income, sustainable choices need

to be front of mind. The ethical reasons for using a tool that can run a life cycle assessment are clear, compelling and obvious, but there’s also a strong practical argument for doing it. First, it flags up inefficiencies within the supply chain, which can lead to cost savings as well as environmental benefits. Second, it often stimulates useful innovation in design and production. Third, legislation increasingly makes manufacturers responsible for endof- life products, and LCA is the best way to prepare for it.

The marine industry takes its lead from automotive in many ways, and LCA doesn’t need to be an exception. The automotive industry has been working with LCA tools for almost 20 years, successfully using them to identify efficiency hotspots and ultimately making sure that each new model represents better environmental properties over its entire life cycle, compared to its outgoing predecessor. Already, automakers have to ensure 85 per cent of each vehicle they sell in the EU can be recycled, and it’s only a matter of time before boatbuilders face similar regulations.

One tangible example comes from Jaguar Land Rover, which has been successfully applying a LCA model, investing heavily in research, engineering and manufacturing to deliver innovative solutions that reduce the environmental impact of their vehicles throughout their entire life cycle. By reducing the weight of a vehicle’s body and components, they can make cars more efficient, while delivering the performance expected by customers. Some of their vehicles use revolutionary all-aluminium bodies that significantly reduce their weight, with a new lightweight modified aluminium alloy that allows for a higher proportion of recycled content, uses 95 per cent less energy to manufacture and produces less waste than virgin material.

LCA tools run on huge databases of industry-specific data, which someone has to research, compile and keep up-to-date. It’s a daunting prospect if you have to do it all manually and start from scratch. The aim of MarineShift360 is to provide a platform that is affordable and accessible to a wide range of marine businesses.

11th Hour Racing teamed up with Into the Blue, a sustainability and sports marketing agency, to develop MarineShift360 – driven by the desire to bring major benefits to the recreational and performance marine industry. Into the Blue’s sustainability manager, Amy Munro, is projectmanaging the development of MarineShift360’s LCA tool: ‘We are actively developing this tool, alongside our pilot partners, so that we can equip the industry with the means to understand product sustainability,’ she says. ‘By gathering reliable data from each partner, we can develop a fully comprehensive database that supports a life cycle assessment tool tailored to the marine industry.’

The result is a bespoke LCA tool from MarineShift360 that is designed to inform internal decision making, and produce robust and reliable data that companies can publicise, after acting on it, to showcase their green credentials. The key here is that the information gleaned from LCA informs design choices. The first step is for designers and decision-makers to have the information at hand.

‘The tool is designed to be accessible to all users, equipping them with life cycle assessments to evaluate and compare materials and processes, investigate alternatives and drive innovation,’ Ms. Munro says. ‘This allows users to make informed, environmentally and economically sustainable choices by bringing whole-life thinking in at the design stage.’

Life cycle assessment (LCA) is the key to a brighter future in which sailing achieves much more of its potential to be an inherently sustainable sport. To make this more easily achievable, 11th Hour Racing is funding the development of a life-cycle assessment tool that’s tailor-made for the marine industry – one key strength of the new LCA tool from MarineShift360 is unrivalled versatility

A key strength of MarineShift360’s LCA tool is its versatility. It’s relevant to a very wide range of companies: suppliers of raw materials like resin, paint, varnish and foam; powerboat and sailboat builders; sailmakers and rigging suppliers; and makers of most types of marine equipment. It doesn’t cover marine electronics at the time of writing, but that’s in the pipeline.

So who is using it? The first wave of pilot partners include RS Sailing, a major producer of sailing dinghies; the raw material suppliers Wessex Resins and Emkay Plastics; and Multiplast, the French hi-tech boatbuilder that has produced dozens of race-winning and recordbreaking yachts.

‘A platform for businesses to compare raw materials is a truly fantastic idea,’ says Emkay Plastics’ managing director, Steven King. ‘We’re excited to see what the future holds for this ambitious and important project. We want to make our customers and potential customers aware that our materials can be used in sustainable practice.’

Yann Penfornis, managing director of Multiplast, says adopting LCA is a moral obligation. ‘We also believe it will be a legal obligation in future and this tool is a perfect way to stay ahead of official requirements,’ he says. The first build project using MarineShift360’s LCA tool will be a new Imoca 60, DMG Mori, for the Japanese skipper Kojiro Shiraishi. ‘We will then be able to compare the results during the construction of a future Imoca that we will potentially start next winter,’ he explains.

The marine industry body ICOMIA is encouraging life cycle assessment and World Sailing has set ambitious targets in its Sustainability Agenda 2030. ‘The build phase of a boat’s life accounts for a significant proportion of the environmental footprint,’ World Sailing’s sustainability programme manager, Dan Reading explains. ‘To address this, we have outlined the requirement for suppliers of new Olympic class boats and equipment to undertake LCA, which will be one of the factors that is considered in the selection process. This has already stimulated some manufacturers to review materials and processes. Applying LCA is the best quantitative approach to measure and reduce embodied environmental impact in the production phase. Ultimately, we can only mandate the use of an LCA tool for certain classes. We hope once the LCA tool is widely adopted within industry, sailors can spec a boat in line with their expectations relating to environmental footprint. It will reduce greenwashing and it will no longer be acceptable to call a boat ‘green’ just because it has a few solar panels.’

Dozens of companies are set to join the MarineShift360 industry collaboration as the pilot roll-out gathers pace, with the full commercial launch of the tool expected in late 2019. Ultimately, its success will be driven partly by sailors themselves. The more we tell our sailmakers, boatbuilders and equipment suppliers that we want our sailing to be sustainable, and the more we ask them about the environmental footprint of the products they sell, the more likely they are to adopt it.

Click here for more information on MarineShift360 »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store