Designed for the next generation of ocean racing sailors, the Jeanneau Sun Fast 30 one design has a huge amount of potential

The growth of the shorthanded racing scene continues and while grand prix custom carbon creations at the top end of the sport seem to be emerging from yards as if spilling off a production line, one of the latest projects to go public is at the other end of the scale, the Jeanneau Sun Fast 30 One Design which is expected to hit the water later this season. This new offshore 30-footer attracted plenty of attention when it was announced at the end of last year. This has been a project that has been bubbling away in the background for a while having been initiated by three international parties, the Union Nationale pour la Course au Large (UNCL), the Royal Ocean Racing Club (RORC) and the Storm Trysail Club (STC) who put out a tender for a design to promote offshore sailing by making it more accessible and affordable for the younger generation.

The competition to create this new 30- footer was won by the combined proposal from designers VPLP and builders Multiplast, both of whom have a great deal of expertise in this field; VPLP for their offshore designs and Multiplast for their abilities in the conception and development of offshore racing boats.

The Sun Fast 30OD has sparked a lot of interest in the shorthanded ocean sailing community but it has been designed as a dual-purpose racer and is equally well suited to fully crewed racing

The one-design aspect of this boat lies at its heart and as such requires the ability and resources of a production builder, which is where Jeanneau joined the party. But, given the French production builder’s ongoing success with its Sun Fast range, to say nothing of the recent impact on the racing scene of the Sun Fast 3300, you may wonder why they felt the need for yet another 30-footer in an increasingly crowded market. The answer was simple.

Bénéteau Group is preparing for the production run in its Nantes shipyard

‘This is a one-design offshore keelboat, designed to keep the cost of competing down and avoid the pressures and expense of optimisation that are frequently incurred in the handicap racing world,’ says Nigel Colley of Sea Ventures T (UK) Ltd, Jeanneau’ s UK agent. Colley and Sea Ventures have played a big part in the development of the shorthanded scene in northern Europe and are keen to see the growth continue.

‘While there has been plenty of focus on the Sun Fast 30OD as a shorthanded boat, it will also be suitable for a crew of four or five, but the first consideration was to create a raceboat for younger people. From there, the second key objective was to create a programme of events for fleets which was why the three clubs were so important. ‘Cost is clearly one of the issues, but not just for the sailors. To get fleets established the 30OD has to be affordable and we are already seeing signs that this is being achieved. It is early days and we are expecting some big announcements to come soon, but there some very interesting and exciting projects developing behind the scenes which look set to provide great access to racing fleets for both youth and corporate racing,’ he continues.

So how much does I cost? ‘The standard price for the One Design version is €142,500 excluding VAT, ex-factory,’ says Multiplast’s commercial development manager Louis Vaquier. ‘This includes a full electronics package from B&G to a high specification with the kind of equipment you have for solo sailing or shorthanded sailing. On top of this price, you only have to add the safety gear and the sails.

The infusion of the new thermoplastic resin involves three components rather than two but that is the only real difference in the production process

‘In the class rules we are limiting the fabrics and the quantity of sails to control the budgets. The sail wardrobe will include a mainsail and two jibs, one will be an allpurpose J2, the other a heavy weather reefable J3 (that serves as ORC sail when reefed), a reaching flying jib and then two asymmetric spinnakers. There are no code zeros allowed. Basically, we're looking for a boat fully equipped, able to do a transatlantic for a bit more than €200,000, including VAT.’

Running costs were also part of the design consideration. ‘Looking back to some of the successful 30ft one-designs in the past, the Mumm 30 is still considered to have been one of great boats,’ he continues. ‘So many people are nostalgic for this period and the Mumm 30’s part in the success of the Tour de France a la Voile and I believe there's clearly a gap to be filled. One of the things that made those boats successful was that they were easy and affordable to manage. So, when it came to the 30OD we were very conscious of these factors, especially when it came to berthing and the size of the boat for the marinas. As a result, we limited the draft to two metres, the beam is just below three metres and the boat length is just under nine metres thanks to a retractable bowsprit.’

But while cost is a major factor, sustainability issues also played a big part in the thinking and the construction of the 30OD is a big step forward. ‘We’re building the boats with Groupe Beneteau in their shipyard in Nantes where the Figaro 3 boats were built,’ continues Vaquier. ‘This yard has a strong history of building offshore racing in the nineties, it used to be Jeanneau Techniques Avancées and now Bénéteau is working towards sustainable yards with the use of a recyclable resin.’

Following several years of research and development with composites supplier Arkema, the Sun Fast 30 One Design will be Bénéteau Group’s first recyclable production boat. Erwan Faoucher is Bénéteau’s research and innovation director. ‘We’ve been working towards the goal of using recyclable resins for three years,’ he says. ‘One of the first major projects was using it for a First 44 to establish whether it could be used on an industrial scale. From there we have used it to build some 6.5m Mini Transat boats and now it will be used for the 30OD which will be the first production boat from Groupe Bénéteau using this system.

The moulds are the same as Bénéteau would use for a polyester laminate

‘Arkema’s Elium resin is thermoplastic and can be recycled which means it can be reheated to take out the fibre and recover the resin. The resin recovered from production waste is also reusable. The interesting aspect is that the recovered resin, which is a monomer, has a good market value.

‘There is very little that we have to do differently in production which makes this process very practical,’ he continues. ‘The moulds are the same as we would use for a polyester laminate and we have the same structural properties, so the design of the boat hasn’t had to change to accommodate the new resin. What does change slightly is the infusion process as there are now three components rather than two, but that is the only real difference. ‘It's a big breakthrough for the industry and Groupe Bénéteau is really proud of it.’

Designers’ Comments

VPLP Naval Architects

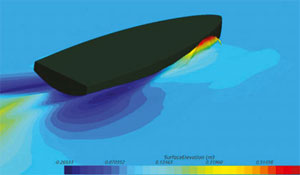

The hull lines feature fuller forward sections and a generous overall beam for a highly powerful hull in terms of righting moment. We have given the boat a narrow waterline beam at low angles of heel to preserve its speed capacity in light winds, and rocker lines with a relatively high aft chine to help the trim of the boat when hiking aft. We think it will be thrilling to sail but easy to control.

One design concept

- Sail area : displacement ratio higher than a typical IRC racer/cruiser

- Not an extreme boat but still more powerful and lively than an IRC-optimised boat

- About 1 ton lighter than a comparable IRC racer/cruiser

- A simple boat: no foils, no water ballast, making it accessible and easy for maintenance

- Certified A4 so eligible for transatlantic racing in a fully crewed or doublehanded format

- Hull made in monolithic fibreglass infused with Elium resin, some reinforced areas

- Hull counter-mould made in fibreglass infused with Elium resin

- Bulkheads made in fibreglass or plywood sandwich with PET foam

- Deck made in sandwich infused fibreglass / Elium and PET foam

- Cast iron keel fin and lead bulb

- Rudders made in monolithic fibreglass infusion with unidirectional carbon reinforced areas

And therein lies another reason as to why the new SF30OD looks set to do well. Being built by the world’s biggest production builder provides clear advantages when it comes to drawing on the expertise of an organisation that is well versed in this type of manufacture. But just how big is the market for another 30-footer?

‘The power of the Bénéteau and Jeanneau Group and their global aspirations for this kind of boat means that they understand where the price point needs to be,’ says Colley. ‘And then there’s the size of the short-handed market in northern Europe, which has exploded in the last two or three years. I don’t see any signs yet of that weakening.

‘For a while during the pandemic shorthanded sailing was the only racing in town and owners of boats that would normally accommodate 10-12 crew came across the shorthanded scene. Interestingly, many of them haven’t gone back. They find the personal satisfaction and sense of accomplishment is greater, the cost is more acceptable and from there success has bred success. You only have to look at the entries for the upcoming Fastnet race where probably one third of the total fleet is going to be double-handed. So the market is big. But we have to make sure that people can access it and that means making it available and affordable which in turn means a well-priced, competitive boat with a good circuit of events’.

Click here for more information on Sea Ventures »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store