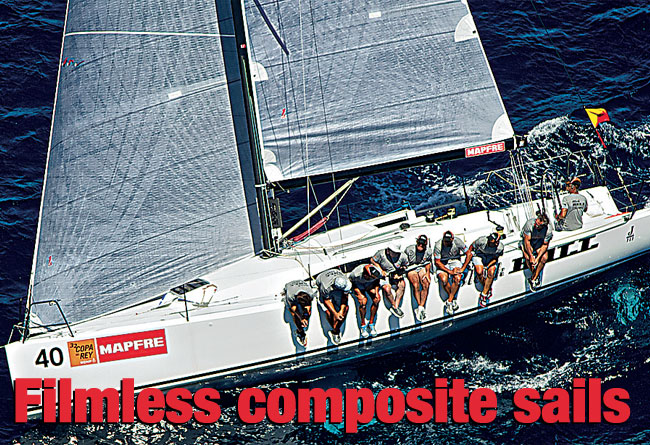

OneSails deliver 4T FORTE – the first ever continuous structural frame composite sail range

OneSails’ next-generation commitment

In 2007 OneSails introduced the first continuous-fibre sails built without the use of resin or glue, eliminating delamination issues at a stroke. Now OneSails goes a step further, by introducing 4T FORTE membranes made from exclusive Multi Micro Structure (MMS™) technology (patent pending).

Multi Micro Structure is the result of more than 15 years of experience and of a life dedicated to high-tech fabrics and the passion for sailing by inventor-engineer PierCarlo Molta. Molta and his team started playing with textiles more than 30 years ago in the family business – a worldwide leader in technical textiles involving safety garments and footwear – located in Tuscany, a district that boasts more than 10 centuries of history in textile manufacturing. His vision to drive composite manufacturing technology from stiff to high-flexibility applications is the inspiration that today makes possible the creation of 4T FORTE sails.

Composite vs traditional Mylar laminate

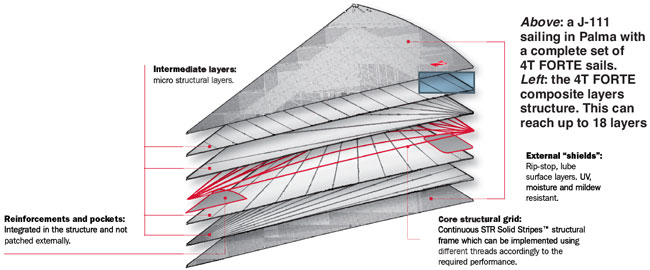

The 4T FORTE composite structure incorporates high-modulus elements such as STR Solid Stripes, a new low-stretch exponent of MMS™ technology that eliminates both the glue and Mylar film, so often the weak element of a laminate sail. Using a multiple micro-layered structure, elements of the membrane are now fused together in a cross-linked, polymerised matrix resulting in a stable, stretch-resistant and more durable sail.

By doing away with both glue and Mylar film these sails are significantly lighter than conventional laminate sails; but not only is 4T FORTE intrinsically lighter than a conventional alternative, but weight saving is further enhanced by the fact that a 4T FORTE membrane does not need to be covered with extra woven taffeta fabric to protect it from UV or improve durability.

Composite in depth

A core structural grid, constructed from high-modulus fibre, takes care of the principal loads in a 4T FORTE sail, while oriented micro layers provide strength in the secondary directions. The entire skin is finally encapsulated between ripstop ‘shields’, which are UV, moisture and mildew resistant.

The whole skin, with its continuous fibres, is vacuum cured in a heat-activated cross-polymerisation process that fuses the components together so that every single element in the structure contributes to shape retention. As a result, a 4T FORTE sail membrane not only exhibits superior structural integrity, but the use of more efficient components creates a sail up to 25% lighter than film-based alternatives.

Replacing carbon and aramid yarns

After many years of carbon being the ultimate fibre in sail - making, OneSails has introduced STR Solid Stripes with a better strength/weight ratio than carbon and a number of other advantages, including being more robust, having higher tenacity plus comprehensive resistance to the harsh elements of the marine environment such as UV, temperature and moisture.

A perfect shape

The shape of the sail is achieved using as a mould a crosscut base layer on which up to 18 separate composite layers are assembled. This allows us to match any desired shape of the sail – even with a very deep luff entry. The composite sandwich is then vacuum cured in a 3D thermo mould to ensure full and accurate control of all curing parameters.

Environmentally friendly sails and production process

Using components derived from recent developments for the military and for biomedical science, MMS™ technology provides a robust and reliable sail skin, manufactured with the minimum of environmental impact while also allowing realistic recycling options.

Using components derived from recent developments for the military and for biomedical science, MMS™ technology provides a robust and reliable sail skin, manufactured with the minimum of environmental impact while also allowing realistic recycling options.

Since glues, resins and solvents have been replaced by heatactivated fusion and the base polymer is 100% recyclable in a standard waste separation process, 4T FORTE sails can truly claim to be ‘green sails’.

Click here for more information on One Sails 4T FORTE »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store