While others rave about the ‘new’ crossover between automotive and America’s Cup technology, one of Italy's most respected engineering institutions has been hard at it for years. The ClubSwan80 ‘My Song’ the latest beneficiary of that hard won experience…

To the majority of us, if you ask the question “where would you find the most refined carbon fibre structures?”, the answer would probably be motorsport or aerospace applications. However, long before any of these sectors embraced composite structures fully, the marine industry had found a home for the growing choices of materials and was pushing the boundaries. Persico Marine stepped into the field once the use of composites was well established and continues to push these boundaries. Not only in the marine field, but anywhere the benefits of a precisely assembled and consistently manufactured solution is needed and where tolerances are tight and failure is not an option.

To many, the idea of a boatbuilding facility cradled in the heart of the foot hills of the Alps, 200 kilometres from the nearest place to launch a yacht (excluding the alpine lakes!) seems crazy. But Persico Marine remains closely tied to the rest of the Persico Group, be that automotive, aerospace, rotomoulding, or architectural, the group grows and learns together. This also allows cross-pollination within the group and an exchange of ideas.

Advantages of automation

In the 1990s to 2000s, the perfection-seeking America’s Cup teams gradually moved away from established boatbuilding companies to a world of dedicated and specialist teams, handpicked and airlifted into a bespoke facility to build one or two boats and then ship their tools to the next project on the next continent. Persico Marine knew that the only way to reverse that trend, and continue improvements, was to show that exactly what had happened in car manufacturing could also happen in the marine world.

Here it is important to keep in mind that automated production is not all about high numbers. It is about it being perfect every time, whether that is only the first and second time, or the 1 millionth time. Persico Marine have the experience and knowledge of the Persico Group behind them, experience, accuracy and repeatability brought to bear in the Volvo Ocean 65 one design and ever since,

Foresight and planning is critical to success in manufacturing perfection. The design process has to consider the manufacturing processes. If the engineering drawings are completed with a handmade, artisan product in mind, then the gains from automated production are not there. Henry Ford did not succeed because the Model-T was built by the best coachbuilders of its time, it was because it was designed to be built on a production line. Had it been built in the standard methods of the day, the workforce would probably have redesigned it on their work benches, or walked out

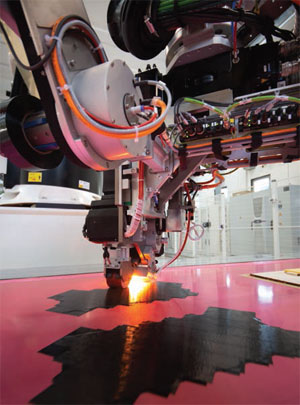

Above: The more complex the component, the greater the benefits of automation

Where the default approach is often in steel or concrete, Persico Marine adds a further dimension to the mix. And the expertise is not limited to things that float, or these days fly above the water. Persico Marine actively encourages all to think of other areas where composites may be the best solution. The benefits of composites go much further than simply making the same item lighter. In an architectural sense, it allows for far more elegant solutions, and more ergonomic and flowing aesthetics. Suddenly, cantilevered platforms are stretching further from the supports and complex inter-twining and compound curved roof beams allow for striking roof lines whilst not only keeping the structure light, but also managing costs where the equivalent steel or wooden structure would take considerably more hours and material to achieve. Using CNC machined tooling, the limits on the shapes of composite structures is constrained more by ideas than solutions.

On the smaller scale, manufacturing in composites also has the benefits of precision. Where laminate thicknesses are measured to the tenth of a millimetre and tooling is manufactured to the same level, resulting components can be constructed to a highly accurate degree and remain extremely strong.

Current customers include NASA and the University of Polimi for whom they are making a telescope and a rocket respectively…

‘We have been working with Media Lario S.r.l. on a very exciting project,’ says Marcello Persico. ‘Construction and milling of steel spider, production and assembling of composite plates and camera support in CFRP (carbon fibre reinforced plastic) with related machining OF ASTHTROS, a highaltitude balloon mission from the NASAJet Propulsion Laboratory for the study of astrophysical phenomena.

‘Short for Astrophysics Stratospheric Telescope for High Spectral Resolution Observations at Submillimeterwavelengths, the ASTHROS telescope is a high-performance 2.5-metre telescope that in 2023 will be carried to the edge of space via a stratospheric balloon. Its launch is scheduled in December 2023 from Antarctica and it will be the largest telescope ever flown on a highaltitude balloon.

‘The telescope is in fact composed of a 2.5-metre parabolic antenna, and a series of mirrors, lenses and detectors designed and optimised to capture light in the far infrared, that is at wavelengths much longer than those visible to the human eye. To do this, it will be transported by a balloon about 150 metre wide at an altitude of about 40 kilometers, a height that will allow it to observe the wavelengths of light, blocked by the Earth's atmosphere.

‘For this project, we have put in play the extensive experience, garnered over the years, in developing and constructing added-value aluminium, titanium and carbon equipment for the manufacture of civilian and military satellite components,’ Marcello Persico concludes.

Ever since the America’s Cup moved into the foiling world, (now approaching a decade ago believe it or not) the chatter about the growing similarities between the America’s Cup and Formula One has only got louder. Looking ahead to the 2024 event, and it seems that a link between the two is all but a must for the teams. However, the transfer of knowledge and information between the automotive industry and the yachting world is not new to everyone. The company grew during the era when automotive production moved from artisan to mass production to mass excellence. The Persico Group grew with it, developing and adapting all the time.

Many would think that as car-making moved from the near bespoke, artisan work of highly skilled coachbuilders to automated systems, an element of refinement would be lost along with that touch of detail and precision. However, the Persico Group was there as the opposite was seen. To get mass production right, you cannot afford to discard sub-quality components, or rework mistakes. Every item off the automated production line has to be as perfect as the last, and the next. The only way to do this is to tighten tolerances and build to higher levels of exactness than the best artisan coachbuilder ever could.

Above: The ASTHROS telescope Persico technology headed to the edge of space

Automated marine production

In the early years of this century production boats and bespoke raceboats were all being built by teams of boatbuilders with every step in the process relying on hand manufacturing processes. Persico had been here before, but now had the experience of designing and manufacturing fully automated production line equipment for the vast majority of the European and American-based car companies. The company has unequalled experience in developing equipment to take a few coloured bags of polymer pellets at one end of a machine and turn out identical, complex car parts at the other, with no artisan in sight. Not only are the fake stitches on the trim of the fake leather always perfectly aligned, but the plush texture and creases in the leather never reveals a flaw or scar.

Clients come to Persico Marine for their reputation of manufacturing the most complex of high-end composite parts reliably and consistently. CNC machines are no longer used just to manufacture moulds, but also to trim components, drill for fastenings and precisely locate joints. Plotters are used to cut materials and now ATLs (Automatic Tape Layers) robots are being used to laminate parts. Every step of the process is now seeing automation as a viable solution.

All this experience, as well as that gained from the Persico 69F International Class – which entered the New York Yacht Club Race Week in Newport with six crews - and the development of the Persico Fly40, has allowed Persico Marine to adopt these automated processes for the next generation of Imoca boats. These increasingly complicated yachts are now the true pinnacle of the offshore and ocean racing world. That focus increases the scrutiny on detail and quality.

With LinkedOut, Persico proved beyond any doubt that they have the necessary skills and knowledge to produce a fast, yet strong and consistently reliable yacht. They are now using that same basic design, with some specific upgrades, for their newest Imoca build. However, this yacht will employ a lot more of the automated processes in manufacture than has been done previously for a oneoff. This allows them to reduce the build time where ATL and CNC do not need to take holidays, but most of all it allows for unlimited precision and accuracy. The old adage of measure twice and cut once also doesn’t apply to these machines. The result of using trailblazing machinery such as the ATL robot, nicknamed Lola, is unparalleled quality, a new and higher standard, one step ahead in terms of building and construction.

With ever-higher quality and control processes in place, reducing the human factor, and ensuring that items are built from the same file they are designed with, Persico is looking to further improve their own and their client’s confidence in their knowledge of what each item is absolutely capable of. With this increased confidence comes the ability to design that into the component from the start, taking a lot of the guess work out of load limits and safety factors, reducing excess and excess weight whilst retaining the levels of strength and reliability desired.

With LinkedOut, Persico proved that it could produce a fast yet strong and consistently reliable Imoca 60.

One step further

Persico will also be taking this a step further this year with another Imoca project, focussing on simplicity and efficiency. To win the Vendée Globe you don’t need the highest top speed, you need the highest average. Here, along with the client and designer, Persico is starting afresh with a design that is focussed on a high average speed that doesn’t rattle the teeth out of the sailors’ mouths, but from concept is also to be built using Persico’s automated approach. The plan is that developing this into a highly accurate series build at a good cost point can be realised. With this and the Fly40, Persico is looking to be able to turn the marine industry on its head and move closer to the automotive industry, where a production boat can be built to as high, if not higher quality and reliability than a bespoke build by the best team of guys you can muster. Reducing unnecessary materials by increasing accuracy makes absolute sense, even from an environmental sustainability point of view. That is only achievable through automation, which is Persico Group’s bread and butter.

In the next 12 months we may see a manufacturing revolution in the top end of the marine industry. There are those who say they used to love the lofting process from a set of offsets, and hand making tools from a stack of wood. But their knees see that as nothing more than nostalgia.

Side by side in the water for the first time: the brand new ClubSwan80 and the Persico60', a cutting-edge motoryacht

New projects

Persico Marine has presented many interesting novelties in recent months. ‘Recently we saw two of our most innovative projects side by side in the water for the first time: the brand new ClubSwan80, a magnificent sailboat, and the Persico60' a cutting-edge motoryacht’, explains Marcello Persico. ‘The eternal competition between wind and engine, both designed by two of the most renowned naval architects, the ClubSwan80 by Juan Kouyoumdjian, the Persico60’ by Germán Mani Frers. The Persico60’ is a unique “toys carrier fast powerboat”, a perfect day-boat where six to 12 guests can motor 45knts safely, bringing along two large jet-skis, a couple of sea bobs and SUPs, while being also able to relax and stay connected to the world thanks to the info-tainment system on the 55” screen. It’s an evolution of the classical tender, a “shadow” yacht, agile, versatile and fast.

‘Each of these boats is unique in concept, style, and development. We have spent months of effort and dedication, proudly arriving at the final result.’

That’s not all, as Persico Marine has announced a partnership with the worldrenowned design studio Zagato that will bring to the market the very first hyperboat.

‘The ultimate advance-composite technology, the design and finishing of a million-euro supercar and a new propulsion that looks and definitely is more similar to that of a jet plane, and it glides on water in total silence… it will be hyper in every detail,’ says Marcello Persico.

Click here for more information on Persico Marine »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store