Zhik R&D manager Tom Hussey says there’s no tougher a sport for testing the waterproofness and durability of modern technical clothing than offshore racing

In the past decade Zhik has listened carefully to the wants and needs of the world’s best smallboat sailors, with Zhik the gear of choice for many of the sailors at Rio 2016 including all the team members of three of the most successful nations: Great Britain, New Zealand and Australia. The gold and silver medallists in the dynamic 49er class – Pete Burling and Blair Tuke (NZL) and Nathan Outteridge and Iain Jensen (AUS) respectively – are among the better-known names who have been wearing Zhik for many years now.

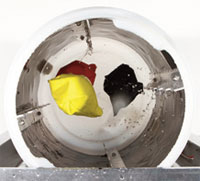

Flexible but dry, Isotak 2 (main picture) and the Zhik accelerated wear machine (above). Test fabrics are made into pockets that contain a control ‘test ball’. These fabric pockets are then placed in a rotating drum that simulates impacts against hard edges and also flat surfaces covered with non-slip grip. Test balls are shaped to simulate the parts of the body and other hard objects that impact a boat through the fabric

R&D manager Tom Hussey says, ‘When we started making neoprene garments back in the early days of the company, it was amazing what sailors were prepared to put up with. Or rather, they didn’t have much choice because most of the wetsuits available had been developed for surfers or athletes from other sports. For sailing they were pretty clunky, heavy and inflexible. Since then we’ve listened carefully to the world’s best and most demanding sailors to give them what they need, to create garments that are warmer, drier, lighter and more durable than what had previously been available.’

Recently Hussey and the team at Zhik have started to ask the same searching questions about offshore gear. ‘The goal was to produce the toughest, most durable kit that we could; it needed to outperform existing kit from rival brands.

‘We’d picked up on comments off the round-the-world boats that some of the supposedly best gear wasn’t making it through an entire long leg without degradation in key features; when we tested used clothing “from elsewhere”, we quickly identified areas for improvement – in materials in particular. So material became our immediate priority.

‘It’s surprising that there hasn’t been a suitable standard to test for waterproof durability. What’s common in the industry is a hydro - static test, where you put a whole lot of water pressure on one side of the fabric and see if it leaks through.’

While this method provides a good indication of the initial waterproofness of a fabric, Hussey says it doesn’t give you any idea of how the textile will maintain its waterproofness through the active life of the product. ‘There is currently no industry standard method that simulates the high levels of wear in the kind of wet, extreme conditions that are experienced by foul weather gear in the most serious offshore events.’

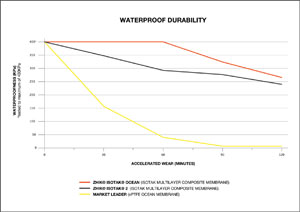

@ 30 minutes of accelerated wear, Isotak Ocean is 2.5x more waterproof than the leading industry brand

@ 60 minutes of accelerated wear, Isotak Ocean is 10x more waterproof than the leading industry brand

[30 minutes of accelerated wear = approx 14 days of extreme offshore sailing or 1yr of regular use]

Accelerated wear

Impacts in 30min = 1,800

Impacts in 60min = 3,600

Impacts in 90min = 5,400

Impacts in 120min = 7,200

Round-the-world leg – 20 days

Hours sailing: 480

Hours active (70%): 336

Average impacts per hour: 8

Total impacts: 2,688

Round-the-world leg – 14 days

Hours sailing: 336

Hours active (70%): 235

Average impacts per hour: 8

Total impacts: 1,882

Regular customer use

30 x 6hr races: 180hrs/108hrs active

3 x overnight races: 72hrs/58hrs active

1 x 4-day race: 96hrs/77hrs active

Hours active total: 242

Average impacts per hour: 8

Average impacts/yr: 1,940

So Zhik approached the Royal Melbourne Institute of Technology (RMIT) to develop a waterproof durability testing method specifically to simulate accelerated wear and tear in wet conditions (when the waterproof membrane is most vulnerable). The method involves placing waterproof textiles in an accelerated wear device that simulates impact and abrasion always in wet conditions. Each textile is pressure-tested to determine waterproofness after defined intervals of accelerated wear (see table).

This has provided Hussey and the R&D team with a much more meaningful way of experimenting with different combinations of materials and bonding techniques. The result is their most recent version of Isotak, a new multilayer membrane. ‘It’s the membrane we use throughout our Ocean range,’ says Hussey. ‘It is in our Isotak Ocean range and new Isotak 2 range, the only difference being that the Ocean has a much thicker, heavier and tougher outer shell fabric. Ocean is our most extreme, most durable product, while Isotak 2 has extremely high levels of waterproof durability, although it’s much, much lighter, less bulky and more flexible.’

Without being prepared to reveal the full magic recipe – the closely guarded combination of materials and methods that have gone into Isotak – Hussey says the secret lies in how you combine various component materials. ‘It’s the knowledge and experience we have gained from exhaustive testing that we believe gives us a competitive advantage; it’s a matter of how we combine all the waterproof layers to make something very, very tough, while also maintaining the same high breathability. The membrane layers that go into Isotak combine to work really well to provide a longlasting waterproof durability.’

Above: not an easy thing to model. Wear calculations are based on an estimated number of impacts encountered in one hour’s sailing, multiplied by the typical hours of activity in one day. That impact total is then applied using Zhik’s accelerated wear machine. For example, 14 days of extreme offshore sailing works out to just over 1,800 impacts, which is equivalent to 30 minutes in the machine

According to independent tests run by RMIT, Zhik’s Isotak outperforms the acknowledged industry leader in offshore garments by a factor of at least 4:1. ‘RMIT’s independent testing has shown that Isotak reaches the same or lower level of degradation after 120 minutes of accelerated wear testing, compared with just 30 minutes for the industry standard.’

Hussey is excited by the results and can’t wait to have some offshore professionals wearing the Zhik garments in next year’s big round-the-world race. ‘But obviously we don’t just stop where we are today. We are always looking to the next thing, and the next. There are lots of different membranes, lamination methods, composites that you can produce; there are a lot of different things coming out all the time. So we’re always keeping an eye on what’s going to work best for extreme sailing that some of our bestknown customers take part in.

‘One of the major problems we come across is a lot of products, particularly with waterproof textiles, are targeted at the outdoor industry and so are frequently geared more towards breathability than outright waterproof durability. So it’s really, really good for climbing a mountain, or cross-country skiing, but not the best product for sailing.

‘You’ve got extremely different environments and requirements in the products. A very small leak in a sailing garment is a fail, whereas when you are skiing down a hill in light, dry snow it isn’t going to worry you so much. Having the absolute highest breathability possible is a much more important factor for some of these other sports.

‘Of course breathability is very important for sailing as well, and Isotak delivers at least the same level as any other offshore clothing product. But compared to land-oriented products we are laser-focused on the fact that you have to ensure that your garments do not leak while you’re mid-ocean.

‘So a lot of what we do is looking beyond the outdoor industry standard and aiming for something that’s best for our intended use. And that’s really where this testing method originates. Because the amount of wear and tear sailors put on their garment is significantly more than in any other outdoor sport – certainly any outdoor sport we’ve been made aware of!’

Click here for more information on Zhik »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store