VO65 class manager James Dadd and the resurrection of the Vestas

I write this sitting in a cramped office I share with Matteo Bisio (Persico project manager), Mike Vittorio (Farr Yacht Design) and Neil ‘Coxy’ Cox (Vestas shore manager) where the sound of grinders against carbon has thankfully now been replaced with what would be the quiet of laminating… if it weren’t for the thumping music that seems to drive all boatbuilders on.

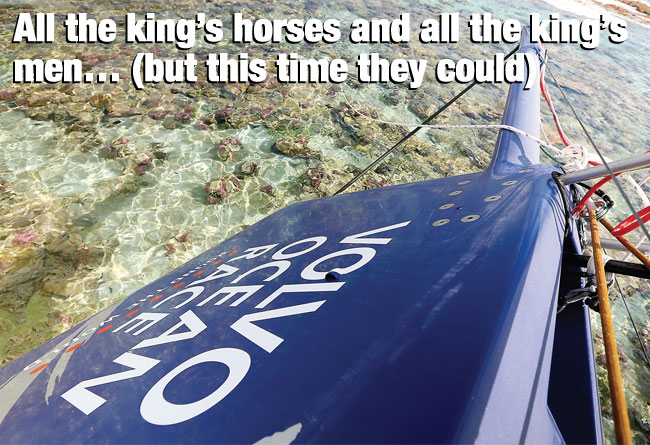

So how is Team Vestas Wind? Well, boat #6 just went back into one piece. Two days ago the original deck met her new hull. Many may look at the wreck that arrived here and consider that the front half didn’t look bad at all, and as such all we needed to do was build a new piece of hull and get back in the water. The reality is that this is not a custom one-off. The only way this boat is going to get back into the race is if she is a true one-design again.

To me there was only one way of making sure the two hull halves lined up and that was to have only one piece. The only alternative was to sand the surviving half back to carbon, remove the bowsprit and collision bow and set her back in the hull mould, then hope that you got it right and scarf the new bit in. This would still create a small join, but with modern techniques that really is a minimal weight gain. But what if the old part didn’t go back in exactly the same place? The only time we would find that out was after she came back out of the mould. By then it is far too late, and not only have we missed the deadline for Vestas to get back into the race but we would have a boat that was of no use to the next race.

To me the decision was simple. For the boat to be a one-design it needed to be a combination of old components and, where they were damaged, completely new components. The assembly then had to be completed in exactly the same way as the original. But there were two big potholes ahead: we didn’t have the time to replace everything that got damaged and at such short notice the original build consortium of Green Marine, Multiplast, Décision and Persico didn’t have the time or personnel to do the work. Fortunately, Persico did have a building they could make available with the hull tool already stored next door.

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store