At first glance the sheer quality of Rondal’s captive winch engineering can make a critical and highly demanding task look too easy...

Superyachts haven’t just been getting larger in recent years. They’ve also become far more strongly focused on sailing performance and helm response in light airs. For designers and builders this means an ever-increasing preoccupation with weight reduction is required, while at the same time rigs are getting larger and the loads that the yachts’ sail control systems have to handle are higher than ever before. Rondal has been a key player in enabling this evolution, not just by building the giant carbon spars for the new generation of mega sloops but also, more recently, creating a super-light version of its unique integrated sailing system to control their enormous sailpower. This includes a remarkable range of captive reel winches, built in carbon fibre and 22 per cent lighter than their aluminium anodized alternative. That’s a potentially massive gain for a racing yacht or a performance cruiser. Installing a full set of Rondal carbon winches can reduce the sailing displacement of a 60-metre yacht by at least two tons.

Rondal’s aluminium captive reel winches – both hydraulic and electric types, currently available in model variants with 2.5-ton, four-ton, six-ton, eight-ton, 12-ton 18-ton and 24-ton pull loads – have earned an enviable reputation for rock-solid reliability. That’s why they’re used on so many of the world’s largest sailing yachts. Not just those built by Rondal’s parent company, Royal Huisman, but also Baltic Yachts, Vitters, Oceanco, Perini, Pendennis, Holland Yachtbouw, Nautor and most other leading superyacht shipyards. After 20 years of service, it’s not uncommon for a set of Rondal winches to need only a small amount of cosmetic refurbishment before being reinstalled for another two decades of sailing.

All Rondal winches are designed with a safety factor of 150 per cent of the pull load built in, so the 18-ton pull load model for example has a hold load of 27tons. Their line speeds are equally impressive at up to 90 metres per minute, delivering a competitive advantage in regattas by enabling fast gybes and swift spinnaker hoists. The winches are optional fitted with load sensors, enabling live read-outs for sails, sheets and halyards. Alarms for safety purposes are available too. All models can be customised for a precise pull load and larger, even more powerful winches can be built on request. ‘For a new project we are developing 48-ton winches,’ sales manager Rudy Jurg reveals. A mini version completes the range, typically used as a forward pull for runners.

All-carbon advantages

The full carbon variants of these tried-and-trusted, high-performance winch designs have been engineered and tested, by both Rondal and by independent external test companies, to ensure that the same very long service life as the aluminium versions can be expected, with the same minimal maintenance requirement. In addition to minimal corrosion, the carbon winch drums are proven to be as impervious to chafe-related wear as their metal equivalents. A range of hybrid inches is also available with aluminium base and carbon drum, and these are currently the most popular option, Jurg explains, as they offer the best ratio of weight saving versus cost.

There are, however, compelling reasons for a new-build yacht to choose the all-carbon option. First, the frame of each winch can be fully integrated into the structure of the hull or deck, eliminating the need for a heavy base plate.

The reduced weight of all-carbon winches could potentially also give naval architects and shipyards’ design engineers more scope to consider alternative locations for mounting them, with less impact on the yacht’s overall weight distribution and stability.

Design and construction

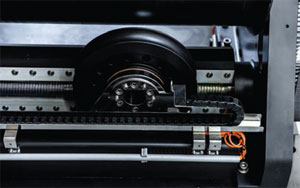

The reliability of Rondal reel winches is about more than build quality, although that is of course crucial. It’s also about design. The line is stored on the drum in a single layer to prevent a second layer from jamming in the first. The drum length is thus dictated by the line diameter and the length of line to be stored. The motor is mounted alongside the drum while the gearbox and brake are inside it.

Next to the drum, a spindle-driven slider ensures the line turns are stored properly. The pitch of the spindle is fixed and the ratio of pulleys is selected for specific line diameter. This gives the possibility of changing line diameters easily when needed in the future. End switches safeguard the use of the winch, which will stop when all but three turns of the line have been paid out, and also as soon as the drum is full.

To eliminate slackness in the line, all Rondal captive winches have an optical sensor that transmits a beam of light beneath the drum. If the line slackens, the turns around the drum will drop and interrupt the beam, generating an electrical signal that stops the winch. At the same time a signal indicating failure of the winch operation is dispatched to the helm and/or winch control position.

Above: a complete set of aluminium captive reel winches for a 60-metre sloop, ready for delivery after being tested at full working load (plus 150 per cent safety margin).

Below: the full carbon models are at least equally robust and powerful but 22 per cent lighter.

Bottom: a spindle-driven slider ensures that all line turns are stored properly on the drum

For something as safety-critical as superyacht sheet, runner and halyard winches, the highest quality materials are required. The carbon fibre winch drums are manufactured using a filament winding process and liquid epoxy resins. The drums are wound on metallic mandrels, post cured, then machined to final dimensions. The frame components are bonded together with mechanical parts while the gearboxes and motors are mounted inside and alongside the drum with fasteners. Finally, a protective clear coat finish is applied to seal the surfaces of both drum and frame.

‘Rondal uses Lloyds-approved prepregs,’ Jurg explains. ‘These are unidirectional high elongation carbon, XC411 biaxial and RC416 woven materials. Curing is done in an autoclave at 120°C for 12 hours to achieve the best possible mechanical and thermal properties.’ Given the superlative build quality of Rondal’s carbon masts and indeed all other components of its integrated sailing system, one would expect nothing less.

Winches are not yet included in the scope of classification societies’ certification requirements but although there is no need for thirdparty assessment, Rondal conducts its own stringent test programme in house. ‘To ensure absolute quality, each winch is evaluated on the test bench to ensure all specifications are met with precision,’ Jurg says. ‘Every winch is tested at full load (plus 150 per cent safety margin), providing yacht owners and skippers with the assurance that the winch system will withstand everything the wind and ocean can throw at it.’

Electric benefits

There are also some compelling reasons for forward-thinking owners, designers and builders to choose electric rather than hydraulic winches. The obvious benefit is peak shaving technology. ‘A conventional hydraulic system must be set up to meet the maximum peak power requirements at all times, resulting in a costly and oversized system for conditions that the yacht will rarely, if ever, see,’ Jurg explains. ‘By contrast, electric winch setups can be laid out for average power requirements because peak demands can always be met by a battery bank and/or an additional generator set.’ Also, the hydraulic board system can be reduced or be made obsolete.

The other big advantage of Rondal’s electric captive reel winches – ideal for the next generation of ultra-low emission yacht concepts that some shipyards are starting to propose – is an option for power regeneration when easing a line and braking. ‘In hydraulic winches this power is instantly converted to heat, whereas our electric winches can feed electrical power back into the system,’ Jurg says. ‘This adds to the battery reserve and, in the event of a blackout, can assist essential sailing systems. Power regeneration not only reduces engine loads and fuel consumption, it also contributes to lower CO2 emissions for the vessel as a whole.’

Peace of mind

Whichever types and sizes of Rondal captive reel winches are fitted, the stand-out benefit is peace of mind for the owner, the skipper and crew, the shipyard and everyone else involved. ‘Our products offer more than exceptional functionality, they provide the assurance that the yacht is equipped with the best there is,’ Jurg says. ‘We are dedicated to finding optimum solutions for every conceivable winch-related requirement. As a result, Rondal winches are remarkable in their simplicity, yet ahead of the game in terms of durability and reliability. We offer peace of mind because we have poured all our sailing and engineering experience into creating virtually maintenance-free and incredibly silent winches that sailors love to use.’ Rondal has a service team for worldwide support and maintenance of its winches. In practice Rondal winches require very little maintenance.

Click here for more information on Rondal »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store