Marlow have been exploring the black art of loop efficiencies, material properties and critical sizing ratios. With Dyneema loops becoming standard everyone has a theory regarding the best way to make them; but Marlow set themselves the task of uncovering the technical mysteries behind Dyneema loop development and manufacture

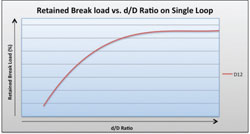

The d/D ratio

The Pin Diameter/Rope Diameter is called the d/D ratio. If the pin or bearing surface is too small the rope will break at this point – however strong. The reason for the failure is that with a very small d/D ratio, significantly more fibres are under compression and therefore not sharing the load (Fig 1).

Fig 1: retained breakload vs d/D ratio

Through testing various d/D ratios in Marlow’s laboratory the company’s engineers found that there is an optimum ratio, at which point a loop of certain strength will stop breaking on the bearing point.

Improving d/D ratio by reducing rope diameter

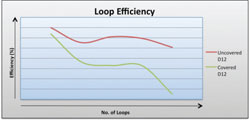

To maintain a high retained break load on a smaller bearing surface a smaller diameter rope can be looped multiple times to maintain the optimal d/D ratio. However, this solution does come at a cost in loop efficiency. Marlow wanted to explore this and therefore tested break load efficiency vs number of loops using their standard 12-strand Dyneema product, D12.

For D12 the loop efficiency decreased as the number of loops increased. However, from testing a sweet spot was identified where efficiency actually increased before continuing to sharply decline as more loops were added. Therefore the optimum loop is a compromise between d/D ratio and the number of loops.

It must also be said that these results were obtained under laboratory conditions, and particular attention was paid to laying out the loops in a methodical and consistent manner to help equalise the forces in each loop as much as possible. This may not be possible in real world applications.

Covered loops

To more accurately replicate the use of loops in the field Marlow investigated covered loops which are increasingly common on racing yachts. Loops were constructed in the same way as before but with the addition of 48 Plait Marlow Dyneema Chafe Cover. Covered loop efficiency showed the same sweet spot for a given number of loops but decreased the efficiency compared to the no-cover option (Fig 2).

Fig 2: loop efficiency for uncovered and covered D12

Covering the loop restricts the load equalisation ability of the individual loops. Somewhat ironically, the cover restricts the movement of the loops across the bearing surface and between each other, meaning that one or more of the loops will be loaded more than the others and will fail before the rest.

Further improvements

With the knowledge that loop efficiency is improved when the rope loops can adjust themselves to equalise the lengths – and therefore load around the loop – it was suggested that coating the rope could also improve efficiencies. Marlow SiliconCoat was added to the D12 for the final tests with the theory that it would help the braids slide over the bearing point and one another to achieve maximum efficiency.

When the covered D12 loops used SiliconCoated core instead of uncoated there was a dramatic increase in loop efficiency.

Conclusion

From the data gathered during this investigation there are a couple of key points to be taken forward. First of which is that the d/D ratio of D12 has an optimum below which the bearing point becomes the weakest part of the rope.

When constructing loops silicone-coated cores will give the highest efficiencies and therefore higher break loads which may allow the use of smaller cores or higher factors of safety. The number of loops is always critical to achieving maximum efficiency and loop specifications should take into account the relevant sweet spot.

Finally, wherever possible the load bearing splice should be located on the back of a bearing point to maintain equal elongation and loading on both sides of the loop.

Please note that the testing under discussion has been carried out using Marlow’s own products and results may not be the same for other products that are constructed differently.

For more information please contact our Marlow Grand Prix Rigging partners who will be able to offer further advice...

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store