Ropes, like people, suffer from fatigue. Unlike people, a good night’s sleep does not reinvigorate them

What is fatigue? Fatigue is any mechanism that reduces the performance of a rope over time in service. This can be abrasion, UV damage, creep, bending fatigue or one of many lesser causes. This article will focus particularly on bending fatigue of high-performance Dyneema cored ropes.

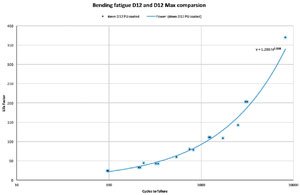

Below: taking account of a logarithmic scale on the x-axis, it is evident that a rope’s fatigue life changes dramatically with even a small change in the life factor; a combination of the critical D:d ratio and load – as is explained in detail in this article.

As modern rope covers are getting more durable, including the increased availability of high-performance blends, they are lasting longer. Also more applications are appearing on boats that place ropes under higher loads and perhaps over smaller sheaves. All this results in fatigue becoming more relevant to sailors, riggers and boat designers than ever before.

A rope is made up of twisted yarns and each yarn contains hundreds of filaments. Every time a rope is flexed the fibres slide across one another, causing the filaments to abrade and eventually to break, thus reducing the strength of the rope. This is a cumulative process and if unchecked the rope will eventually have a strength less than the working load, resulting in an in-service failure.

The rope pictured above shows typical fatigue damage – but note that the broken filaments are inside the braid rather than at the crowns of the plaits, as would be expected if the cause was external abrasion.

There are many factors that influence rope fatigue, the major ones being:

Material: Most modern high performance ropes have a Dyneema core; this material has good fatigue resistance. All the following information is based on testing of Dyneema 12-strand ropes.

D:d ratio: The ratio of the diameter of the sheave that the rope is being bent around to the diameter of the rope. The larger this ratio the better the fatigue life; a small increase in D:d can significantly improve rope life. As a ‘rule of thumb’ doubling of the D:d ratio will approximately triple the fatigue life.

Load: Like D:d the load that the rope is under can significantly alter fatigue life. In testing a 35% increase in load was shown to halve the fatigue life.

Coatings: Most HMPE ropes have a coating or impregnation of some sort, normally there to improve handling, splicing and abrasion resistance and to impart a colour to the rope. These coatings can also alter the fatigue life, with some standard PU coatings actually reducing fatigue life. Special lubricating coatings can extend the rope’s life very significantly.

Rope design: Factors such as twist level, braiding pitch etc can all have an effect on a rope’s fatigue life.

How can rope designers and users make sense of all these parameters? One method is to combine the Load and D:d into a single ‘life factor’ by multiplying the coefficient of utilisation (safety factor) and the D:d ratio, ie a rope with 1,000kg MBL working at 200kg on an 8:1 sheave will have a life factor of (1000/200) x 8 = 40.

Combining these parameters allows us to quickly compare the major factors for each rope design and so start to make judgements as to how a system’s design will affect the life of the rope and how long it can remain in service.

Other factors to account for:

Pre-stretching This does not significantly alter the fatigue properties but it does reduce the diameter for a given strength, which alters the D:d (for the same-sized sheave) and therefore the life factor. What this means is that, compared to a non pre-stretched rope swapping to a stronger heatset rope at the same diameter will give a small improvement in the fatigue life, while swapping to a smaller rope with the same strength will give a small reduction.

Heat As the rope is cycled heat is generated in the braid and the faster the cycling the more heat builds up. At small diameters this isn’t a problem and cycle speed doesn’t affect the life. At larger diameters, though, the heat generated at higher cycle speeds can affect the fibres, reducing the fatigue life. In extreme cases it is possible to melt a rope’s core through the heat generated.

Rope fatigue A huge subject and this article only scratches the surface. However, Marlow’s extensive and ongoing test programmes not only mean that our ropes are designed to optimise performance, but that we are able to offer clear technical advice based on empirical evidence and with race-proven results.

Paul Dyer, technical manager, Marlow Ropes

Click here for more information on Marlow Ropes »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store