TeXtreme® is taking carbon fibre to the next level

Carbon fibre is not just carbon fibre… the possible variations make all the difference from a material that is ‘just’ light and strong, to something that can be both super-light and super-strong when the application requires and the budget allows. And with their TeXtreme product Swedish-based Oxeon is taking things up another step with the development of a novel method of aligning fibres in carbon tapes in such a way as to further maximise the properties of a material that is already amazing but that is today too often taken for granted.

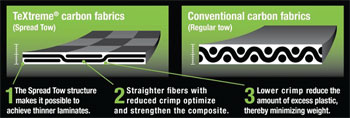

Oxeon achieves this advancement through taking an ingenious geometric approach: by spreading the individual fibre tows into flat arrays rather than twisted round yarns. With this geometry these Spread Tow unidirectional tapes thus come out much thinner than conventional tapes, and have a higher density of carbon that is also using its mechanical strength more efficiently, directly along the axis of the tape. The fibres are also more evenly distributed, with the filaments aligned in the tape to minimise the crimp that will inevitably compromise both stiffness and strength.

The result is a very flat, very thin, unidirectional tape that can be laid out on its own or further woven into fabrics. Woven with these Spread Tow tapes, the spread tow fabrics also acquire the same properties of low crimp and thin cross-section. TeXtreme tapes and fabrics thus achieve a maximum strength until breakage that, remarkably, is twice or more that of most conventional carbon fabrics.

Laminates built with TeXtreme are thus able to find a much wider array of applications where thinness and high-strength are necessary and conventional woven laminate materials would simply not achieve the same performance.

Because the inherent value of TeXtreme is in its fibre geometry, it is also possible to customise the properties needed by altering the fibre materials in the tapes and fabrics. For example, among carbon types High Strength, Intermediate Modulus or High Modulus fibres may be used, but also other fibres such as Innegra, Twaron, Kevlar, Dyneema or Zylon (also known as PBO) may be used to improve impact tolerance, varying the modulus within the fabric, while also varying tape orientation to achieve the maximum benefits of the TeXtreme itself .

The Spread Tow materials being so thin and pliable also makes the use of TeXtreme unusually versatile and has already found widespread applications in many other technical sports aside from sailing. These include Formula 1, the America’s Cup, NASCAR, IndyCar, Le Mans endurance cars, cycling, ice hockey, surfing, motorcycle, rowing shells, golf, tennis, skis and snowboards. TeXtreme is also employed in a wide variety of aerospace and industrial applications.

‘Use of TeXtreme in performance sailboat construction is just getting started,’ said Tomas Sjöö, marine sales manager for the product. ‘Boatbuilders are rightly cautious in adopting new materials and techniques in their business, where major failure is not an option yet cost control still remains critical. Reputations are carefully built and vigorously protected and making changes to a build process can be difficult.

‘But among those who have looked seriously at our products, there has been widespread satisfaction with the results achieved.’

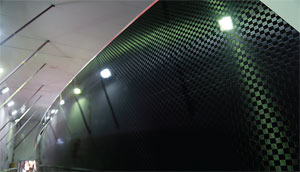

Fabric patterning that you can be proud of… the first of the HH66 Morrelli&Melvin-designed luxury performance cats built at Hudson Marine under the supervision of Paul Hakes shows off the quality of the finished appearance using precisely and finely woven TeXtreme carbon fabrics. The TeXtreme solution is already in common use in racecars, aerospace and military applications

Fabric patterning that you can be proud of… the first of the HH66 Morrelli&Melvin-designed luxury performance cats built at Hudson Marine under the supervision of Paul Hakes shows off the quality of the finished appearance using precisely and finely woven TeXtreme carbon fabrics. The TeXtreme solution is already in common use in racecars, aerospace and military applications

One of these is Paul Hakes at Hudson Marine, a highly experienced builder of high-tech racing yachts and performance watercraft, whose new ultra-modern HH66 catamarans are launching soon and use TeXtreme fabric for not only its high strength features, but also for the aesthetics that can be delivered in the finished laminate: when clear coated these fabrics can look spectacular and evoke an unmistakable imagery of high-technology fabrication.

‘I have nothing but great things to say about TeXtreme,’ said Hakes. ‘We have found it to perform at or above expectation in its structural characteristics and in slotting into our existing lamination and fabrication processes, and the clear coat finish of the outer skins is simply stunning – I’ve been waiting years for a material with these properties to produce with confidence a large clear coated carbon boat.’

But Hakes also confirms what Sjöö has said about a builder’s understandable reluctance to take on a new material: it was five years ago that he first saw TeXtreme and even started to think about its potential.

‘It was at METS that I saw this new approach to the material and started talking with them,’ said Hakes. ‘What intrigued me was the flat weave because I knew that even though conventional carbon weaves look great in clear finish at close range, this disappears at a distance. With the right finish this weave could look spectacular even from far away, which is what is needed for large yachts. But I was still not sure if it would suit our fabrication process.’

So Hakes set out to prove that TeXtreme could do the job with a rigorous regimen of panel testing for not only ease of lamination, postcuring properties, rigidity, strength and durability, but also the real-life finish quality and its ability to hold up under punishing UV exposure.

‘We were provided with sample materials to make 4m x 8m test panels where we assessed the key criteria over lengthy trials:

- ‘cosmetics: did the fibres remain straight and aligned, with no bends and kinks that could be viewed under a clear finish?

- ‘any infusion problems with the resin not penetrating into the fabric – it turns out that this system infused better than our conventional weave carbons.

- ‘resin compatibility: we found that the material infused best with a room temperature resin and a custom hardener that gave us a 10° higher heat distortion temperature.

- ‘ensured there was solid adhesion to the 25mm core-cell material.

- ‘minimal shrinkage and print-through problems associated with the heat distortion temperature effects.

- ‘post-curing to 85°C for 20 hours to stabilise the laminate.

- ‘solar UV resistance, the test panels with a sanded finish placed in the sun reached temperatures of 80°C, whereas the clear coated panels were 10° lower due to the reflection of heat energy away from the smoother panel surface.’

The HH66 designers at Morrelli&Melvin also did their own structural engineering to ISO codes, and found that use of a custom 160g/m2 TeXtreme weave gave a 20% increase in strength and stiffness over conventional carbon fabrics.

‘TeXtreme looked great, it infused well, it was stable and it met all our structural and aesthetic requirements,’ said Hakes. ‘But because the material looked so perfect in the finish, we had to ensure clean room conditions during lay-up to prevent any foreign dust from getting into the laminate.

‘And when doing the lay-up, working with a 66ft luxury performance cat we needed to get this right first time… there are no second chances when using 300m2 of any valuable and highperformance composite material!’

Per square metre the Spread Tow materials used by Hakes are a little more expensive than conventional weaves, but the total composite cost can sometimes come down; and Hakes feels the extra cost still delivers value for the most demanding applications.

‘The TeXtreme suppliers are great to work with, they understand the need for customisation and they are very responsive. This material is well worth the extra cost, and even being in China their pricing and delivery terms are good for us.

‘And the end product is stunning.’

Click here for more information on TeXtreme® »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store